International® eMV™ Series

INTERNATIONAL® EMV APPLICATIONS

The new eMV™ Series suits any straight rail application* and with a vehicle performance of 335 hp and battery capacity of 135 miles, the new eMV is ready to help you get the job done, no matter what job comes your way. Its new thoughtful design with improved visibility through sloped hood and breakaway mirrors provides additional safety for your crew.

*No PTO application, ePTO under development.

WHAT MAKES THE EMV™ SERIES UNIQUE?

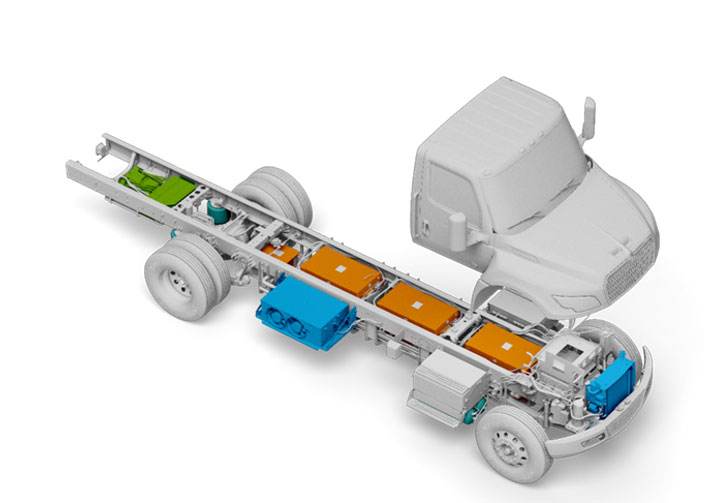

Built on the same proven foundation used in the diesel MV Series, some key placement changes were made, including the batteries and battery controller; the motor controller and motor; the radiator and Battery Thermal Management System (BTMS); as well as the air tanks and air bag suspension.

Key features of the new eMV include:

- 210kWh battery pack

- 135-mile range

- Electric drive motor

- Industry leading 3 levels of regen braking

- AC/DC charging and capability with up to 125kWh DC fast charge

- VTG capability and a new full digital display

MAINTENANCE SCHEDULE

It’s no secret electric vehicles require less maintenance. With substantially fewer parts, an electric motor simply does not have the maintenance or service requirements of an internal combustion engine. Plus, thanks to regenerative braking, the standard brakes last much longer between service intervals.

Take these off your service plate:

- No engine oil maintenance

- No transmission maintenance

- No fuel filters

- No turbos, no EGR, no injectors

- No engine air filters, no MAF, no O2

- No after treatment